SOURIAU - SUNBANK Connection Technologies excels in applying an array of coatings and specialized finishes that help prevent wear to components when utilized and exposed to the harshest environments.

Our solution

Dry film / Solid film lubricants

Solid or dry film lubricants are a high performance coating used for reducing friction, galling, seizing and protection against corrosion. Dry or solid film lubricants greaty improve the wear life of parts and are less prone to collecting soil particulates and can often outperform traditionally used oils and greases. These specialized lubricants are applied on a designated area and then cured and bonded through a heating process.

From left to right: plated, masked

Xylan® and Polysulfide

Xylan®

SOURIAU - SUNBANK Connection Technologies often utilizes this technology as a solution to prevent wire chafing and friction in various componentry. Parts are masked to selectively coat desired areas for Xylan® (PTFE - like coating) application. To ensure proper coating adhesion, parts are placed inside an oven for curing.

Polysulfide

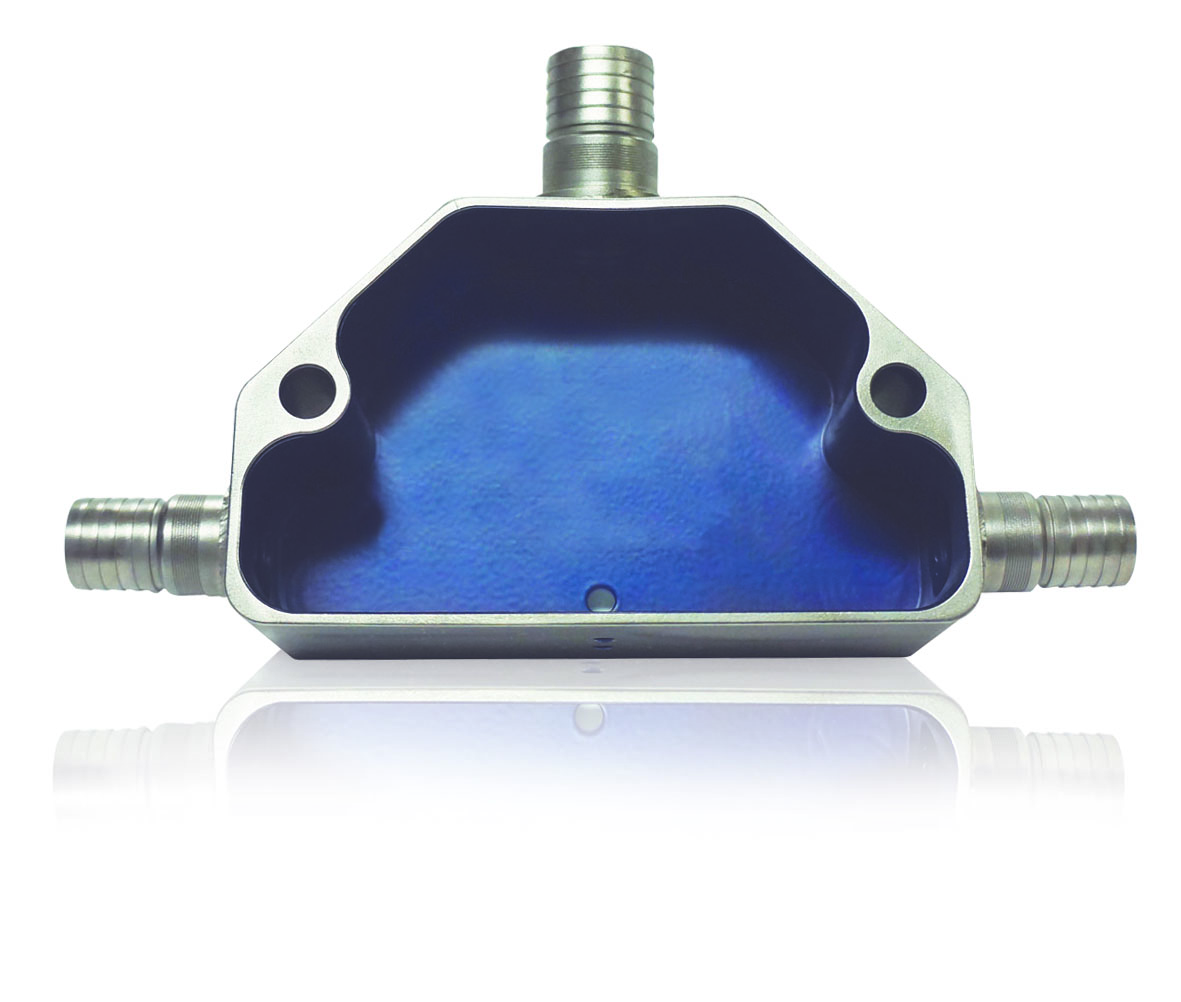

This Elastomeric sealant is commonly used for its excellent resistance to liquids, solvents, oils/lubricants and fuels. It is a great alternative solution to using conventional oil resistant and weather resistant gaskets and can also be used as an additional sealing layer.

Polysulfide stripes can be applied to very specific and small areas to create a barrier for disimilar materials

Anti-abrasion Xylan® inner coating